Features and Options

| Pressure Vessel | Standard | Optional |

| A wide range of chamber sizes (160 to 17000 liters) are available to meet customer needs. | ||

| AISI 316Ti stainless steel chamber | ✓ | |

| AISI 316Ti stainless steel chamber | o | |

|

Internal chamber surface polish

<0.6 Micro Ra. |

✓ | |

| Internal chamber surface polish up to 0.2 Micro Ra. | o | |

| Electropolish (chambers less than 1300 liters) |

✓ | |

| Electropolish (Bulk chambers > 1300 liters) |

o | |

|

Jacket: Stainless Steel 304

|

✓ | |

| Jacket: Stainless Steel 316L / 316Ti | o | |

| Stainless steel bottom frame | ✓ | |

| Jacket cooling system (for liquid load sterilizers) |

✓ | |

| Air operated gasket | ✓ | |

| FDA approved sealing materials | ✓ | |

| Insulation: Mineral free rock wool | ✓ | |

| Insulation: Foniteck | o | |

| Air Steam Mixture (ASM) | o | |

| Hot Water Shower (HWS) | o | |

| Cleaning-in-Place (CIP) | o | |

| Cabinet | o | |

| Bio-Shield Frame (BSL 1-2) | o | |

| Bio-Shield System (BSL 3-4) | o | |

| Seismic-Tie-Down (STD) | o | |

| Control System | Standard | Optional |

| Allen-Bradley Control System | ✓ | |

| English language operating system | ✓ | |

| 5 Level password operating system | ✓ | |

| Graphical display of Temperature and Pressure trend charts |

✓ | o2 |

| 7" Advanced user-friendly touch screen control system |

✓ | |

|

15" Advanced user-friendly

touch screen control system |

o | |

| Built-in printer with full record of cycle data |

✓ | o3 |

| Chart Recorder | o | |

| SCADA | o | |

| Barcode Reader | o |

2 Additional languages are available

3 Various upgrade options are available

| Piping and Components | Standard | Optional |

| Primary: Full Sanitary Piping | ✓ | |

|

Primary: Simplified Sanitary Piping

|

o | |

| Secondary: Stainless Steel piping & components with Tri-clamp connectors |

✓ | |

| Sanitary Air Filter (0.003 μm) in stainless steel housing (PALL) |

✓ | |

| 4 point temperature sensors | ✓ | |

|

4 point pressure sensors

|

✓ | |

| 2 Flexible PT 100 (in chamber) | ✓ | o1 |

| 2 Validation ports 1 | ✓ | o1 |

| Absolute Pressure Gauge | o | |

| Air Detector | o | |

| Steam Quality Test | o | |

| Multipurpose Valve | o | |

| Water Recycling System | o | |

| Automatic Filter Water Intrusion Test (WIT) |

o | |

| Biohazard Thermal Sterilization | o | |

| Biohazard Exhaust Filtration | o |

1 More are available upon request.

| Validation and Support Document | Standard | Optional |

| DQ/IQ/OQ | ✓ | |

|

P&ID

|

✓ | |

| SOO | ✓ | |

| 21 CFR part 11 | ✓ | |

| Orbital welding reports | ✓ | |

|

Software Sequence of Operation (SSO)

|

✓ | |

| FAT/SAT Protocol | o |

Design and Construction

Chamber and Jacket Construction

The inner walls of the 316L stainless steel chamber have a surface level polish less than 0.6 μm [SF6] (specific custom polishing values less than 0.4 μm [SF4] are available upon request). The chamber is constructed to be drainable with smooth, rounded and sloped surfaces to enable proper drainage and cleaning. The chamber is fully jacketed.

Biological Seal (bio-shield)

The bio-shield provides a hermetic seal for maximum biological containment between the differently qualified zones. It is constructed from stainless steel plates and flexible neoprene insulation to prevent micro-organisms from passing between zones. The bio-shield includes a jacket frame and wall frame.

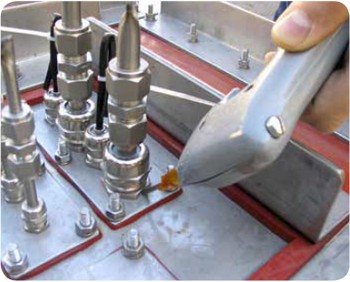

Sanitary Piping

Full sanitary primary piping with tri-clamp connectors, orbital welding and sanitary level components. Tuttnauer sanitary piping is designed and constructed in accordance with cGMP requirements. Our sanitary piping's allows full drain ability to minimize risk of contamination.

Sanitary Air Filter

Full sanitary primary piping with tri-clamp connectors, orbital welding and sanitary level components. Tuttnauer sanitary piping is designed and constructed in accordance with cGMP requirements. Our sanitary piping's allows full drain ability to minimize risk of contamination.