Liquid Loads

Liquid Load Fast Cooling Applications

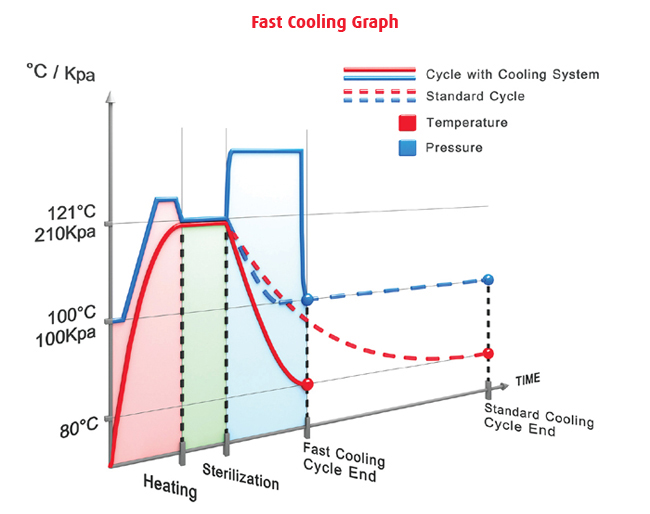

Sterilizing liquid requires longer heating and cooling times for completing a cycle, especially with sensitive liquid loads.

When time is critical advanced optional fast cooling features are available with Tuttnauer’s laboratory autoclaves that prevent a sudden drop in chamber pressure which can cause liquids to boil over.

When time is critical advanced optional fast cooling features are available with Tuttnauer’s laboratory autoclaves that prevent a sudden drop in chamber pressure which can cause liquids to boil over.

Fast Liquid Cooling

After sterilization is completed, compressed air is passed through a microbiological filter into the autoclave chamber in order to prevent a drop in pressure which also prevents load deformation, cracks or spills. Cold water is then circulated through cooling pipes that rapidly reduces the chamber temperature and that of the liquid load to a safe temperature.

Tuttnauer’s fast liquid cooling technology reduces cycle time by as much as 75% and minimizes load exposure to high temperatures.

Benchtop ELC Models

Super Fast Liquid Cooling

In addition to fast cooling, an optional fan can be applied to further circulate the compressed air in the chamber.

This speeds up the heat exchange during the cooling stage in order to safely achieve super fast cooling of the liquid load under pressure.

This speeds up the heat exchange during the cooling stage in order to safely achieve super fast cooling of the liquid load under pressure.

Tuttnauer’s accelerated fast liquid cooling technology reduces cycle time by as much as 90% and minimizes load exposure to high temperatures.

F0 – Protect Your Liquid Media, Save Time, Save Energy

An additional challenge with liquid sterilization is the need to prevent extended exposure of liquid media to high temperatures, which may harm the quality of the liquid media. The advanced F0 ooptional feature assists in minimizing the time liquids are exposed to high temperatures during sterilization thereby protecting liquid media, saving your laboratory time and reducing energy consumption.

Isothermal Processing

For Agar Preparation

Optional isothermal cycles are typically used for preparing agar and other biological media. Tuttnauer offers a flexible isothermal cycle with a temperature range from 60°C to 95°C that allows for gentle heating and cooling down of agar.