Fast Liquid Cooling Option

Reduced Cycle Times with Optional Fast Cooling

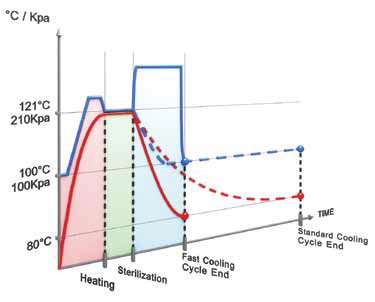

Tuttnauer’s accelerated cooling technology reduces cycle time and protects the load by minimizing its exposure to high temperatures. Rapid cooling typically reduces cooling time by as much as 75%. After sterilization is completed, compressed air is passed through a microbiological filter into the autoclave chamber. In this way pressure drops are prevented. The pressure increase prevents load deformation, cracks or spills.

Tuttnauer’s accelerated cooling technology reduces cycle time and protects the load by minimizing its exposure to high temperatures. Rapid cooling typically reduces cooling time by as much as 75%. After sterilization is completed, compressed air is passed through a microbiological filter into the autoclave chamber. In this way pressure drops are prevented. The pressure increase prevents load deformation, cracks or spills.

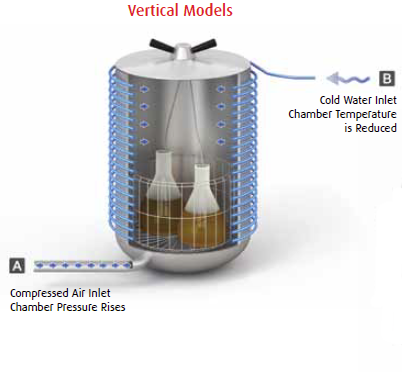

Extra Cooling by Water Circulation

The vertical autoclave chamber is surrounded by coils that are filled with cold tap water to help rapidly cool down the chamber to a safe temperature. When the liquid’s temperature reaches the final set temperature, the cooling stage is complete.

The vertical autoclave chamber is surrounded by coils that are filled with cold tap water to help rapidly cool down the chamber to a safe temperature. When the liquid’s temperature reaches the final set temperature, the cooling stage is complete.

More time is required for liquids to reach sterilization temperature compared to non-liquids. Tuttnauer’s advanced laboratory autoclave line is equipped with a flexible temperature load sensor, which is placed in a reference vessel, ensuring that the set sterilization temperature is actually attained when sterilization begins. Sterilization is initiated only when the load sensor reaches the preset required temperature.

After sterilization is attained, the autoclave door cannot be opened immediately, but only after the liquid has properly cooled down. Tuttnauer’s cooling method prevents a sudden drop in chamber pressure which can cause liquids to boil over.

An additional challenge is the need to prevent media exposure to high temperatures for a long time, for the concern that it might harm the quality of the media. Tuttnauer offers advanced options that minimize the time liquids are exposed to high temperatures.

Fan Assisted Cooling

An additional feature that further enhances the cooling stage is the optional radial ventilator. The fan circulates the hot air, inside the chamber, transferring the heat to the cooled chamber walls or cooling coils. The overall chamber and load temperature rapidly drops.