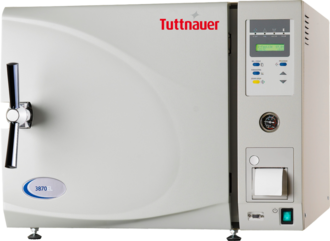

With higher capacity and better performance, Tuttnauer's EL Laboratory line of fully automatic, microprocessor controlled, benchtop, steam sterilizers provides safe, economical and effective sterilization. Integrated reservoir for water feed, with water level control and steam recirculation saves on demineralized water consumption and enables the autoclave to be independent of a water supply. External heating elements make the sterilizer easy to clean.

The Tuttnauer benchtop front loading laboratory autoclave is available in chamber sizes from 23 liters to 160 liters. EL models have an advanced microprocessor based control panel.

Sterilization Applications

The various applications can be carried out using the autoclave’s standard programs. Additional options ensure more control over results and optimal, safe and repeatable sterilization processes. For special applications, our experienced team will customize a suitable method for you.

- Liquids such as nutrient media and buffer solutions

- Solid items such as pipettes, tubes and filters

- Glassware and plastic articles

- Waste sterilization

Quality Features

- The chamber is constructed of long lasting 316Ti grade stainless steel with superior corrosion resistance

- The generator is made from stainless steel

- The autoclave automatically switches to standby mode if no buttons or switches are operated for four hours

- The autoclave is designed for easy servicing allowing maintenance access to all components

- Drain Protection: The exhaust drain is mixed with cold tap water that cools the exhaust’s temperature before reaching the drain

Control and Documentation

Control Features

- High precision control system for perfect sterilization results

- Password protection allows for secure access control

- Independent temperature and pressure monitoring

- Cycle information recovery in the case of power failure or cycle interruption

- Fail Alert – Indicates cycle failure or interruption

- Door Alert – Indicates the door is unlocked

- RS 232 PC Connection Port for direct software updates and remote maintenance

Built in Printer

The laboratory line can be supplied with a built-in printer to document the performed cycle, in addition to a comprehensive LCD display. This feature is optional.

ADMC Software

The ADMC software allows complete control and monitoring of up to eight sterilizers. The software retrieves data, creates graphs, tables and print outs, controls the autoclave and shows real-time data.

Model Chart

| Type | Chamber Dimensions (ø x depth) (in mm) |

Chamber Volume (in Liters) |

External Dimensions (W x H x D) (in mm) |

|---|---|---|---|

|

2540 EL

|

250 x 400

|

23

|

510 x 365 x 545

|

|

3150 EL

|

310 x 500

|

40

|

600 x 450 x 695

|

|

3850 EL

|

380 x 490

|

62

|

660 x 525 x 695

|

|

3870 EL

|

380 x 690

|

85

|

660 x 525 x 875

|

|

5050 EL

|

500 x 500

|

110

|

880 x 700 x 767

|

|

5075 EL

|

500 x 750

|

160

|

880 x 700 x 967

|

Sterilizer Directives and Standards Compliance

Tuttnauer’s high quality laboratory autoclaves comply with the strictest international directives and standards.

- Pressure Equipment: PED 97/23 EEC, EN 10028-7, ASME Code Sec VIII

- Safety: IEC/UL/EN61010-1, IEC 61010-2-040, EN 61326

- Sterilization: DIN 58951 Series, ISO 17665-1:2006

- Quality System: ISO 9001:2000, ISO 13485:2003

Safety Features

Door Safety

The autoclave lids are designed with a number of independent mechanical and digital safety features.

- A safety device prevents the operator from opening the door when the chamber is pressurized

- Steam is not allowed to enter the chamber when the door is open

- A cycle cannot start if the door is open or not properly locked

- The door cannot unlock until liquid temperature reaches the predetermined end temp

- The door cannot unlock until chamber pressure reaches room pressure

- Temperature Activated Door Lock - The door will not open until the temperature is below a specified safe level

General Safety Features

- Double Independent Monitoring: The combined electronic and mechanical monitoring guarantees accurate results. The operator has two independent means to monitor temperature and pressure.

- Safety Valves: The chamber is equipped with safety valves – if the pressure exceeds the allowed limit the safety valves will discharge

- Built-in Steam Generator Safety: A water level monitoring system maintains a constant water level and ensures safe operation of the heaters